Red, White, and Blue Emergency Vehicle Strobe Lights - blue and amber emergency lights

Organic peroxideformula

If your company requires shipping organic peroxides overseas, it is critical that you transport them in the proper containers. Organic peroxides can be extremely dangerous to transport, and you don’t want to take any chances with the shipping containers you use to get them where they need to be for a variety of reasons.

Organic peroxideuses

Klinge has been providing safe transport of goods for chemical and pharmaceutical companies for more than three decades and is the smart choice when it comes to shipping organic peroxides. To talk to a specialist or for a quote on our containers, contact Klinge today!

Oil-Dri Corporation of America is a leading manufacturer and supplier of specialty sorbent products for consumer and business to business markets. Founded in 1941, the company is a vertically integrated, global organization with extensive mineral reserves, innovative product development, efficient manufacturing operations, and effective sales and marketing strategies. Oil-Dri’s products are sold into the pet care, animal health and nutrition, fluids purification, agricultural ingredients, sports field, industrial and automotive markets. Oil-Dri controls hundreds of millions of tons of specialty mineral reserves, including calcium bentonite, attapulgite and diatomaceous shale. The company’s mines and manufacturing facilities are located in Georgia, Mississippi, Illinois, and California. Oil-Dri also operates processing plants in Canada and England and has subsidiaries in Switzerland, China, Indonesia, and Mexico. The corporate office is located in Chicago, Illinois and two research and development facilities are nearby in Vernon Hills, Illinois. Oil-Dri is a family-controlled and operated organization that emphasizes honesty, integrity, and accountability. The company is dedicated to fulfilling its mission to Create Value From Sorbent Minerals.

Organic peroxidedangers

Oil-Dri has a strong commitment to our investors. We have paid cash dividends continuously since 1974 and have increased dividends annually since 2003. In fiscal year 2023, the annual common stock dividend totaled $1.12 per share.

As our organization grows, we find value in reflecting on the milestones that have led us to where we are today. This video gives a snapshot of past, present and future. Visit our history page to experience an interactive timeline that highlights the people, discoveries and events that have contributed to our success.

The Nick Jaffee Center for Innovation and the Richard M. Jaffee Laboratory for Applied Microbiology in Vernon Hills, Illinois serve as the nucleus for Oil-Dri’s research, development, and technical support activities. These facilities feature research laboratories for extensive testing, a pilot plant that simulates the production processes of our manufacturing plants, and a Biosafety Level 2 lab that enables the examination of materials to accelerate Oil-Dri’s microbial research and new product development.

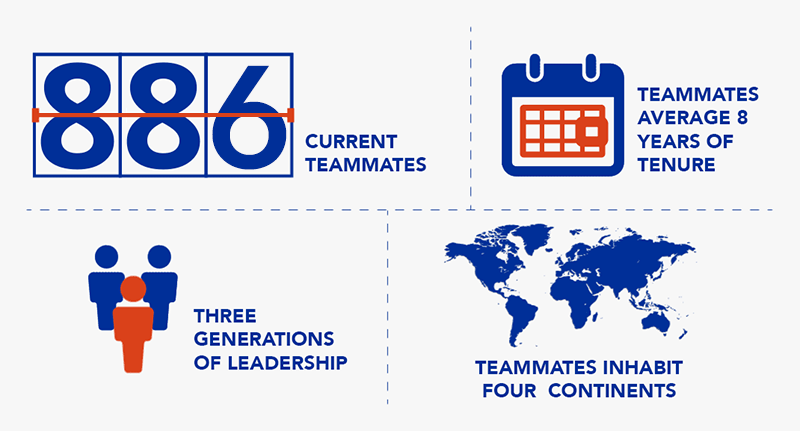

We became successful by standing on the shoulders of those who came before us and by building a team that embodies the same core values upon which Oil-Dri was built. We are 886 strong, living on four of the world’s seven continents. We care about our team and statistics prove that our team cares about us. Our average teammate tenure is eight years. We pride ourselves on Oil-Dri’s three generations of leadership. Visit our Careers page to learn more about our culture and browse open positions.

Organic peroxideflammable

Organic peroxideproducts

This amazing mineral combined with the resourceful and pioneering spirit of our team members allows us to create sorbent products for a diverse group of industries, spanning both consumer and business to business markets.

Reefer containers are essential to the safe transportation of organic peroxides that require temperature control. During road transport, the cooling units for these containers must be mechanical and be able to work independently of the truck engine. The truck driver should be able to read the temperature of the cooling compartment at all times, and the truck must have an alarm system that indicates if the container exceeds the alarm temperature. Spare parts and service providers for the refrigeration system must also be available.

class 5.2:organic peroxideexamples

Klinge has developed an extremely reliable container for Class 5.2 dangerous goods transportation. Our Dual Redundant Refrigerated Container & Integral Genset has two full capacity reefer units and automatically switches to the backup in an emergency. It complies with the Internal Maritime Organization’s regulations for the transportation of certain organic peroxides and therefore, also comes with a diesel generator set that will power the units during truck transport or external power supply loss as well as internal explosion-proof fittings.

An important factor in organic peroxide safety is self-accelerating decomposition temperature (SADT). The SADT of an organic peroxide is the lowest temperature at which it will experience self-accelerating decomposition in one week in a typical vessel or package. At the SADT, the heat evolution becomes unbalanced due to the decomposition reaction and the rate of heat removal from the package.

While organic peroxides can look innocuous, they can actually be quite hazardous. They can be toxic or corrosive and can cause a health hazard if handled, inhaled or swallowed. They can rust and destroy metals. Most importantly, as mentioned above, the high oxygen of the peroxy group means a level of flammability and combustibility.

Organic peroxideexplosion

To define organic peroxide, it is a carbon compound with two linked oxygen items (peroxy group). Because of the high level of oxygen, organic peroxides can create a substantial fire and explosion risk. Organic peroxides are chemicals that are found in a wide range of industries, especially the plastic and rubber industries. They can act as accelerators, curing agents, hardeners and catalysts and serve a variety of other useful purposes. While they are typically found in solid form as a powder, they can sometimes come as liquids or pastes, as well.

If the heat removal is too low, the temperature inside the package rises, and the decomposition rate increases uncontrollably. Self-accelerating decomposition occurs when the decomposition rate is fast enough that it generates heat faster than it can dissipate into the environment.

Organic peroxideexamples

Reefer containers are also used during sea transport of temperature-controlled organic peroxides. These containers typically have a redundant cooling system. These containers also have an alarm system to warn of temperature deviations — usually also tied to a GSM or Satellite monitoring system.

For some of what are called class 5.2 organic peroxide, it takes very little to catalyze them. A slight amount of heat, shock or friction can cause them to combust and burn extremely quickly. For this reason, it is incredibly important to store them in a temperature-controlled and constantly monitored container during transport.

Some peroxides are highly unstable and must be refrigerated to prevent self-accelerating decomposition. Others are more stable and can be stored safely at normal ambient temperatures. To determine the maximum temperature at which it is safe to transport an organic peroxide, it must be tested to determine its SADT.

Innovation is the backbone of our company. In the last 5 years we have invested nearly $12 million dollars in new product development and technical support for our company’s comprehensive product portfolio. This investment in the future enables us to continually produce unique mineral solutions for our customers.

13322766566

13322766566